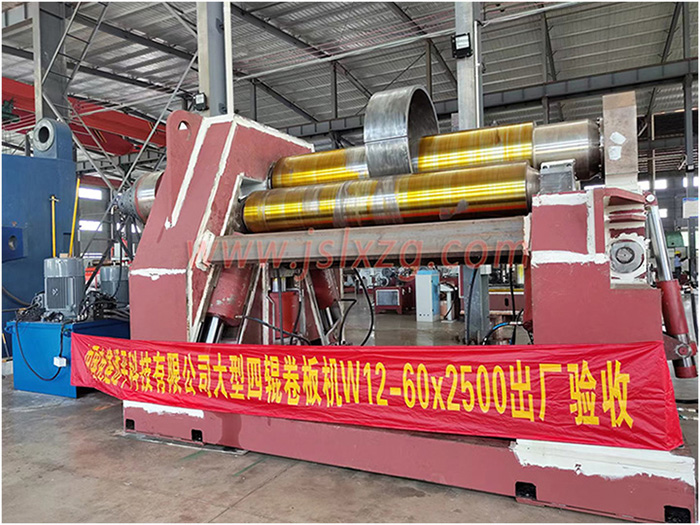

This is a large four roll plate rolling machine, with a mesh welded structure on the frame. This structure can effectively support the frame to resist the forces generated during the plate rolling process, making the frame more stable and less prone to deformation.

All work rolls are made of 42CrMo steel, which is quenched and tempered after rough machining, HB260-300. After finishing, medium frequency quenching HRC45-52. Surface grinding and polishing treatment to prevent scratches on rolled sheets.

The driving system adopts a dual drive system, with the upper and lower rollers driven by independent hydraulic motors and planetary reducers (and equipped with an overload protection system); Dual drive can provide greater tension for steel plates, allowing for smaller diameters and thinner steel plates to be rolled.

The side roller movement method adopts a linear sliding rail type, and the side roller is driven by a hydraulic cylinder to perform up and down reciprocating motion in the linear rail. Compared to the arc swing arm type plate rolling machine, its structure is more sturdy, the pre bending effect is better, the control accuracy is higher, the service life is long, and the maintenance is simple.

The hydraulic system is an independent oil circuit, consisting of two parts. One is the main transmission part, which provides power for the upper and lower work rolls. The other is the auxiliary transmission part, which lifts and lifts the lower and side work rolls; Inverted flipping provides power. Each oil pipeline motor drives a high-pressure oil pump for independent system oil supply, and adopts a stacked valve structure to adjust the movement speed of the main oil cylinder to meet the working speed of the side and lower rollers under different working conditions.

The CNC system is based on Siemens PLC as the core, equipped with Smart700IE V3 color display, and can display the current displacement values of each movement of the rolling machine during operation. It can preset the displacement values of each roller and form a reliable and high-performance control system with PLC.